Spotlight

on

Taiwan

TWS

19

FREJOTH

(Hall 1, B34)

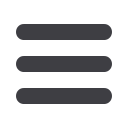

We, Frejoth International Ltd., are going to display

our most advanced machines such as the 5-axis machining

center ATVMC-5XA at the 2015 EMO fair.

This traveling machining center is built with 5-axis

simultaneous function and swivel head on the B axis.

The overall dimensions of its fixed table are about 2400

x 700 (mm) . Equ i pped

with a 320mm diameter

rotary table and a strong

t a i l s tock on A ax i s , i t s

movable sections create

two machining areas on

the f i xed t ab l e , sav i ng

significant time during

l oad i ng and un l oad i ng

s t a g e s . R e g a r d i ng t h e

machine head, a swivel

spindle, ISO40 - DIN 69871, is mounted with a powerful

29.3KW/160NM motor. It allows for reaching a speed of

14000 RPM, while rotating from -120° to +120°. For greater

performance and efficiency, this machining center uses

Heidenhain ITNC 530 controller. Another model is available,

ATVMC-5XC (See picture), with a horizontal rotary table,

added or built-in to the fixed table.

www.frejoth.com.twCAMPRO

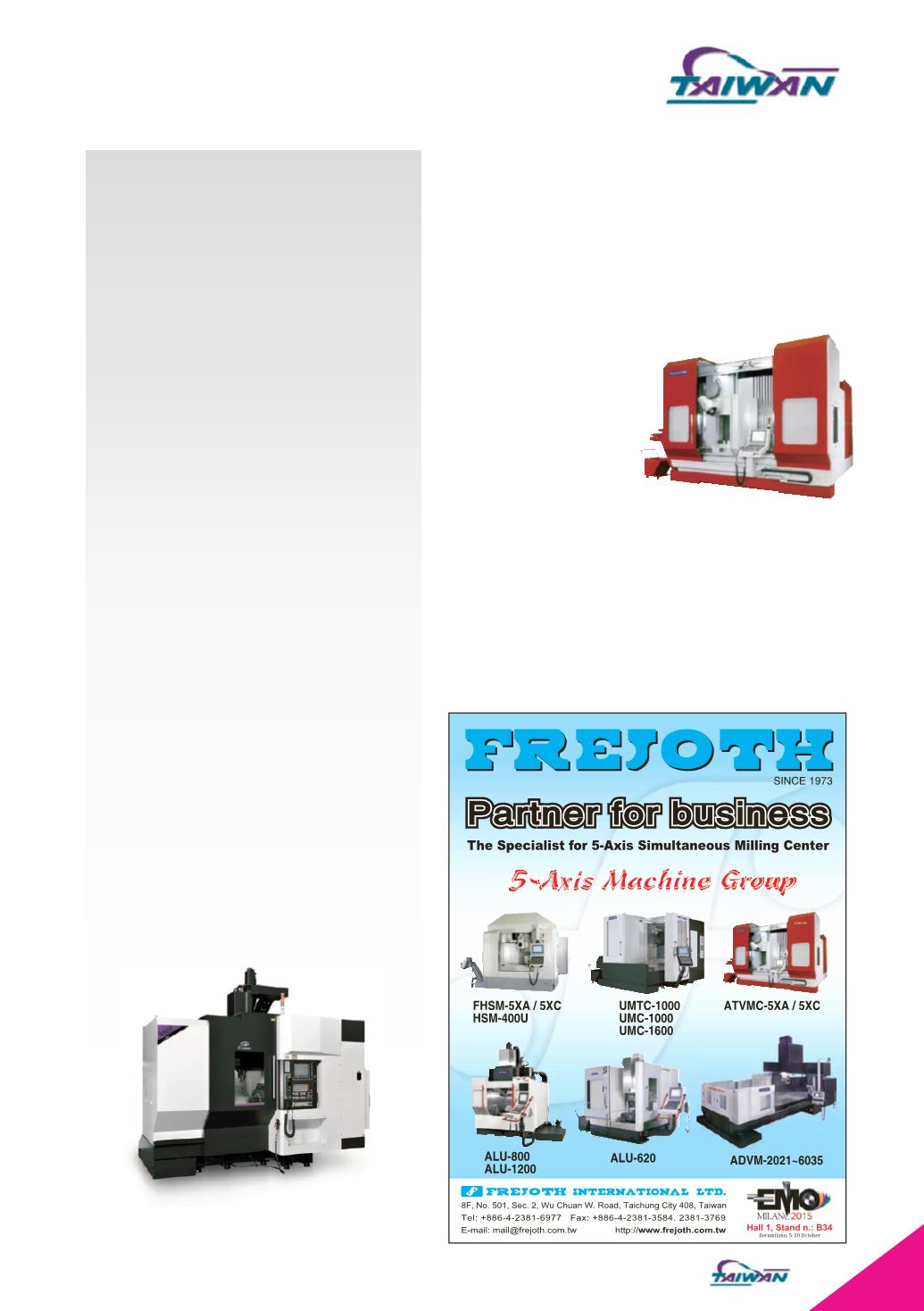

The new Camp r o U s e r i e s 5 - a x i s

machining center provides simultaneous

5-axis motion, giving you the versatility

of small-sized machine and competitive

components without the expense of a large

footprint swivel head machine.

The U series is designed with a super

heavy mono-block cast base constructed

with FC300 cast iron. Mono-block column

structure delivers the ultimate stability for

machining precision components. Combined

with linear scales on X/Y/Z-axis and A/C-axis

(with encoder), it offers the highest level

of accuracy with excellent positioning. This

machine is also equipped with 45mm roller

linear guide ways on all three axes for heavy-

duty cutting.

Drilling may seem to be a simple

operation, but many modern components

require a large amount of holes to be drilled

on different axes. With a traditional 3-axis

machine, this can easily lead to multiple

setups, taking valuable machining time and

reducing your profitability.

With the 5-axis trunnion type machine,

you have the capability to drill these holes

across many axes with 120° travel, saving you

time and money. U series is also coming with

a 12,000rpm built-in spindle and powerful

28kW motor to maximize your cutting

performance and efficiency. Finally, the

Heidenhain iTNC530’s sophisticated functions

and the double arm rotary table (A/C-axis

supported) will allow you to finish machining

parts in a single setup without repositioning.

www.campro.com.tw