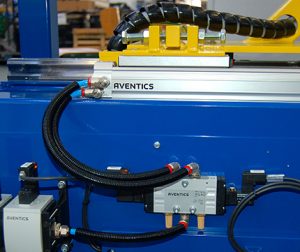

Strapping machines Fromm with Aventics pneumatics

In the context of the historical and successful partnership with Aventics, Fromm Packaging Automation chose pneumatic specialist’s FRL unit AS03 and the TC15 series solenoid valves for a custom-made packaging solution with semi-automatic strapping machines. These machines throw the strap around the bundle, even on the opposite side of the operator and inside the pallet, and are the optimal solution fo bulky or irregular products, which cannot be easily packed in an automated way.

The strap is tensioned and welded with a manual device, from Fromm Packaging Automation. The machine support and simplifies the operator task that can operate independently, without the support of further operators. The solution allows to strap and film products in row and not in row, until 20-30 packages per hour. In case of production requirements and higher volumes, Fromm is able to install more strapping machines one next to the other, so that only one worker can handle most packages in series. The products range of Fromm includes machines for plastic, steel, film wrapped with vertical and horizontal axis rotation.

The Aventics FRL unit AS03 chosen have a special modular design, offers high performance, flexibility and high energy efficiency and employs special ultra-light polymers, making AS systems compact but resistant and efficient at the same time, with a reach capacity of 14.500 l/min. Besides the standard functions of filter, regulation and lubrication, Aventics’ AS system are provided with other tools, such as shut-off valves and distributor with non-return valve. Fromm also chose solenoid valve type TC15 providing high reliability, high capacity and an efficient solution in a wide range of applications.

Contenuti correlati

-

IO-Link and energy saving in air treatment with Emerson and CoreTigo

Emerson is creating sustainable solutions for its customers with CoreTigo’s wireless industrial automation technologies. The collaboration tackles the challenges of compressed air management in machinery, ultimately reducing energy waste and CO2 emissions, while enhancing maintenance efficiency and...

-

Magnetic bearings SKF increase sustainability in air compressors

SKF’s magnetic bearings, which can rotate at up to 50.000 rpm, are now playing a key role in reducing CO2 emissions across a range of industrial applications, including compressors. The technology has been indeed selected by Finnish...

-

Oil-free air compressors with new CompAir D-Series

CompAir launches a new range of oil-free rotary screw compressors of the D-Series, which covers air and water-cooled models from 37 to 75 kW. The series is available in both fixed and regulated speeds (RS) delivering ISO...

-

Sustainable compressors Mattei in the CZ Loko locomotives

A key focus on energy savings and environmental sustainability in the compressors technology, combined with the continuous research for improvements in quality and performance, convinced the Czech company CZ Loko, Europe’s second largest locomotive supplier, to choose...

-

Fluid Power Made in Italy for China with Aignep branch company

Aignep, Italian company based in Brescia and specialized in the fluid power sector, flew to China to open a branch company in Wuxi (Jiangsu). The project, which became reality in January 2019, marks the intention of the...

-

Ceramic desiccant Atlas Copco for compressed air dryers

Atlas Copco presents Cerades, a patented solid ceramic desiccant for compressed air dryers which offers operators of compressed air significantly better air quality, lowering pressure drops by up to 70%, with improved energy efficiency, lower service costs,...

-

Oil monitoring system on compressors by Mattei

The Italian company Mattei has launched an oil-monitoring system for its compressors that keeps a constant watch on the quality and temperature of the oil, supporting good operations and a longer life of the compressor. With an...

-

Pressure sensors IMI Precision Engineering with IO-Link capability

IMI Precision Engineering has expanded its range of pressure sensing technology solutions with the introduction of two new electronic pressure sensor options, which include IO-Link connectivity. The IMI Norgren 54D and 34D Electronic pressure sensors can be...

-

Aluminium pipes Aignep in a new 168 mm diameter

Aignep has launched the new 168 mm diameter for pipelines of the Infinity line, dedicated to installations for compressed air, inert gases and vacuum. Infinity line is one of the Italian company’s flag ships, composed of a series of...

-

Mattei compressors for Pelliconi’s bottle tops production in China

Compressed air by Mattei is a crucial factor in the Chinese production of the Italian company Pelliconi, a specialized manufacturer of tops and closures for bottles and containers in glass, plastic and aluminium since 1939. Pelliconi opened...