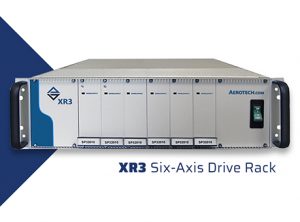

Six-axis drive rack by Aerotech

Aerotech launched the XR3 six-axis drive rack with field replaceable, front-mounted, 3U plug-in amplifiers, that supports both linear and PWM topologies.

The XR3 can control any combination of brushless, DC brush, or stepper motors at up to 320 VDC operating voltage and 30 A peak current capability. Both the current loop and servo-loop are digitally closed to ensure positioning accuracy and rate stability. This processing capability allows the XR3 to provide loop closure rates up to 20 kHz and to handle both digital and analog I/O processing, data collection, process control and encoder multiplication tasks in real time.

Standard features of the motor include per-axis brake control logic, auxiliary encoder feedback, analog I/O expansion, 16 opto-isolated inputs, 16 opto-isolated outputs, up to 12 high-speed differential outputs, 3 PSO (Position Synchronized Output) external sync inputs, 3 TTL or isolated PSO outputs, 1 opto-isolated data-acquisition input, and 2 STO (Safe Torque Off) sense inputs. The XR3 supports open-loop control, standard square-wave encoder feedback, analog input feedback control, and absolute encoder feedback.

The XR3 include three different optional levels of integrated encoder multiplication, including options that support dual-loop encoder feedback, drive-rack cooling, rack or slide-type mounting, and multi-axis Position Synchronized Output (PSO) I/O for low-latency, position-based process control. The device contains two configurable power supply sections to support a variety of motors with different operating voltages. When only one motor voltage is required, the power supply sections are joined together for even higher power capability.

Contenuti correlati

-

Textile automation by Moog Animatics

Moog Animatics presents the integrated system SmartMotor for yarn and thread winding and spooling applications in the textile industry. The solution, distributed in Italy by Smart Automation, includes a brushless servomotor with driver and CNC card housed...