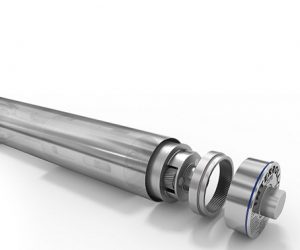

Oil-free drum motor Interroll suitable for food industry

Interroll launched a renewed version of its oil-free drum motors, first introduced by the company back in 2010. The new version of the oil-free drum motor is based on the improved Interroll Drum Motor platform, that has been on the market since 2017.

Synchronous oil-free drum motors are by nature very efficient, which means less heat losses and a much higher power density, as opposed to asynchronous oil-free drum motors which are prone to overheating and power reduction and therefore loss in torque. Compared to standard drum motors, the oil-free motor’s performance is only minimally impacted by the different type of lubrication. Also, compared to a standard asynchronous motor, oil-free synchronous motors are stronger and better performing. But they require a frequency inverter and speed and torque are slightly reduced compared to a standard synchronous motor lubricated with oil. However, high-speed applications are still possible if the belt pull force is sufficient. This is also true for low-speed applications.

Oil-free motors are a proven solution for many applications, in particular the food industry, for example for transportation and packaging of lightweight goods such as candy, chocolate or pralines. Food manufacturers who have to comply with certain restrictions regarding food contamination benefit indeed from this new option. Oil-free drum motors can be used for any application where the belt moves slowly (i.e., when the production process is in steps and accuracy is of paramount importance, like portioning and cutting for instance).

When installed correctly, Interroll Drum Motors have no leakage issue, an essential requirement in sensitive production processes. The oil-free drum motor makes the entire production flow safer as it eliminates any potential risk of oil contamination. It works well in cool temperatures, which are often a requirement in the food manufacturing sector. In certain industries such as fish processing, the European Hygienic Engineering and Design Group (EHEDG) recommends the use of oil-free motors.

Contenuti correlati

-

Metal cutting in Spain, Sorma announces new opening of Sorma Ibérica

The Italian company Sorma announces the opening in Barcellona of Sorma Ibérica, expanding its presence in the markets of Spain and Portugal. The new company is already operational as master distributor in Spain and Portugal for the...

-

BLM Group strengthens its presence with new office in Mexico

BLM Group has reinforced its presence in Mexico, inaugurating its new office in Mexico City, located in the municipality of Cuautitlan Izcalli. BLM Group has been present in the Central American state since 1992, supporting customers with...

-

Cutting tools, Hoffmann Group and Iscar join forces

From 1st October 2023, the Hoffmann Group will offer the complete Iscar tool range throughout Europe and supply it from its central warehouse LogisticCity in Nuremberg. The underlying agreement was signed by the Hoffmann SE representing the...

-

CNC plasma and waterjet cutting, Esab acquires Swift-Cut

To grow its leadership in the global fabrication, cutting equipment and consumables markets, Esab has acquired Swift-Cut, a leading manufacturer of light industrial CNC plasma and waterjet cutting machines based near Birmingham, England. “Swift-Cut solutions enable fabricators...

-

Esab rebranding for HKS weld monitoring and analytic equipment

Esab announces that all HKS brand equipment, which includes the flagship WeldQAS Quality assurance system for real-time monitoring and recording of arc characteristics, have been rebranded as Esab products. HKS Prozesstechnik GmbH was founded in 1994 in...

-

Wear resistance and longer tool life with Kennametal in cast iron milling

Kennametal has introduced the two new indexable milling grades KCK20B and KCKP10 for higher wear resistance and up to 30% longer tool life when machining cast iron and compacted graphite iron components. Both grades offer higher productivity...

-

High cutting performance toric carbide endmill from Mikron Tool

Cutting tool manufacturer Mikron Tool expanded its Crazy Mill Cool P&S milling cutter family, developed for roughing and finishing operations, with a toric version. The new carbide endmill from Mikron Tool combines the strengths of milling and...

-

Red Dot Award to Esab’s wire feeder for product design

The Robust Feed portable wire feeder by Esab has received the highly coveted Red Dot Award: Product Design 2021. This is the second Red Dot award Esab has won for product design. The brand also won in...

-

PPC solid-carbide barrel milling cutters from Hoffman Group

Hoffmann Group has expanded its tool family for Parabolic Performance Cutting (PPC) to include a new PPC indexable insert and Garant PPC solid-carbide barrel milling cutters for high-alloy and hardened steels. The PPC process represents a further...

-

Uniparts spare parts for Cam-operated automatic lathes

The Swiss company Uniparts extends the life of cam-operated automatic lathes with a wide offering of spare parts and attachments for most of this kind of machinery by Tornos, such as model MS7, and also for automatic...