Deep-hole drilling IMSA with NSK DIN-standard ball screws

The new MF1000-3T deep-hole drilling machine from IMSA takes advantage of the benefits provided by NSK’s DIN-standard ball screws for the European machine tool market. The long-standing partnership between IMSA and NSK dates back many years and involves the development of numerous machine models. IMSA intends to show the new MF100-3T at the EMO Milano machine tool exhibition in October 2021.

Established in 1988, IMSA is located in Barzago, northern Italy, from where core business centres on the design and manufacture of deep-hole drilling and gun-drilling machines. As a leading company in its field, there are now more than 500 such IMSA machines operational worldwide. Applications are wide and varied, but many focus on the gun drilling of mould tools for the automotive industry. Seven IMSA models for this purpose came to market between 2014 and 2019 alone. Thanks to a series of options, each standard base model is custom-built according to the specific requirements of customers, although the company can also design and manufacture completely bespoke solutions.

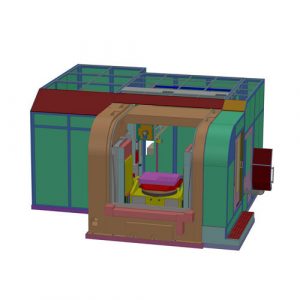

To help maximise machine performance, IMSA has for many years relied upon ball screws and linear guides from its preferred linear motion partner, NSK. The company is now repeating this tried and tested formula for its latest deep-hole drilling machine, the MF1000-3T, which will be able to produce holes up to 1000 mm deep (depending on tool diameter). Equipped with a tilting head, the machine will also offer the capability to perform milling operations, while an 80-station automatic tool-change magazine and automated pallet changer will facilitate unattended workpiece machining.

To help maximise machine performance, IMSA has for many years relied upon ball screws and linear guides from its preferred linear motion partner, NSK. The company is now repeating this tried and tested formula for its latest deep-hole drilling machine, the MF1000-3T, which will be able to produce holes up to 1000 mm deep (depending on tool diameter). Equipped with a tilting head, the machine will also offer the capability to perform milling operations, while an 80-station automatic tool-change magazine and automated pallet changer will facilitate unattended workpiece machining.

NSK’s ball screw, which conforms to DIN 69051 (ISO 3408) with regard to both dimensional and tolerance classes, meets IMSA’s performance demands in term of speed, accuracy, load capacity and rigidity. The first NSK DIN-standard ball screw order is due for delivery in May 2021 to meet the requirements of a prototype MF1000-3T. NSK RA65 roller guides will also form part of the order.

Manufactured in shaft diameters from 32 to 63 mm, and with leads from 10 to 40 mm, NSK DIN-standard ball screws offer a speed factor of 160,000 dn. This performance level makes them ideal for use without restriction in high-speed machining applications where very accurate positioning is also required. In addition, the smooth running properties of the ball screws ensure the least possible vibration in the linear system, while simultaneously reducing noise levels.

Contenuti correlati

-

Expanded inch-to-metric range of rigid couplings from Ruland

Ruland Manufacturing is giving users access to a wider range of off-the-shelf couplings by expanding its inch-to-metric stand coupling product line with new rigid couplings. This expansion is the latest addition to the company’s inch-to-metric, standard coupling...

-

Quick and accurate digital boring head setup with Seco Tools

Seco Tools presents Seco Axiabore and Axiabore Plus digital axial boring heads, developed to eliminate tedious, inaccurate boring head adjustments that can lead to scrapped parts. Its wide digital display helps for quick, efficient adjustment and setup....

-

Circuit verification Siemens certified for UMC 28nm process technology

Siemens Digital Industries Software announces that its Analog FastSPICE (AFS) platform is now certified for United Microelectronics Corporation’s (UMC) 28nm high-performance, low-power process technology. Customers using Siemens‘ AFS platform can now leverage the performance enhancement and power...

-

Scan arm longevity in Europe awarded by Faro

Faro Technologies announces that the Swedish Öhlins Racing, a pioneer in advanced suspension technology, is the winner to its ‘Oldest working FaroArm in Europe’ contest. Öhlins Racing has put its 1993-era Faro Metrecom Arm to good use...

-

Atex directly operated proportional valve by Parker

Parker Hannifin made available its patented VCD drive technology also for explosion risk environments, with the DFplus proportional DC valve D1FP, Atex and IECEx certified. The valve differs from the standard version with its pressurized encapsulation for...

-

Roller pinion system Nexen in stainless steel

Nexen introduced a corrosion-resistant stainless steel version of its patented precision roller pinion system RPS. The RPS engages two teeth simultaneously to achieve superior accuracy with zero backlash at any length. The solution uses needle bearings to...

-

High precision electromagnetic gauges F.lli Giacomello

The Italian company F.lli Giacomello presents the small levels IEG-Inox-1M-SF, electromagnetic gauges customizable for length and intervention points. The devices are entirely constructed in AISI 316 stainless steel, thus suitable in the production processes of chemical, pharmaceutical...

-

Robots Comau in Brasil and USA

Comau showed its latest robots in two important events in Brasil and USA last May, the Feimec fair in São Paulo and the Industry week manufacturing & technology conference & expo in Rosemont, Illinois. At the exhibition...

-

Robots ABB small and accurate

ABB launched its Robots Arm (Scara) IRB 910SC compact family, with maximum payload of 6 kg, with a design emphasizing speed and accuracy. The Scara robots are available in three configurations, IRB 910SC-3/0,45m, IRB 910SC-3/0,55m e IRB...

-

Machining optimized by Okuma

Okuma presents the Servonavi application, aimed to increase accuracy in machining operations, available for almost all of the manufacturer’s machining centers, lathes and multitasking machines. The solution, part of Okuma’s line of Intelligent Technology, provides automatic and...