Innovative bearing solutions Schaeffler for wind turbine manufacturing

Schaeffler presented at WindEnergy Hamburg last September innovative bearing solutions for wind turbines manufacturers and operators, aimed at increasing performances thanks to higher power density, longer operating times and lower carbon footprint, increasing sustainability of wind farms.

At WindEnergy, Schaeffler introduced its new hydro-dynamic plain bearings and related engineering for planet gears. This is because a thorough understanding of the systems and new simulation and calculation methods, as well as the corresponding tools, is required to ensure that the bearings function smoothly. Increasing power density in wind turbine gears, combined with the demand for reduced weight and cost, requires in fact new bearings concepts. With traditional planetary gears, this leads to a larger number of planets with smaller diameters, known as ‘multi-planet concepts.’ This means that not enough space is available for rolling bearings in the planet gears. Hydro-dynamic plain bearings are the solution here because of their low cross-section.

Performance optimization has also brought about a marked trend towards adjusted bearings with two tapered roller bearings in an O arrangement. The increased support spacing of this bearing arrangement reduces the inner bearing loads, whereby the bearing can be made smaller and lighter. To ensure that the adjusted bearings continue to function year on year, Schaeffler engineers fall back on various options from the tapered roller bearing construction kit. Selection takes place as part of a multi-level system simulation, which takes into account the effect of forces and deformation on the bearings in operation. The bearing details are checked, and in a simulation, the correct pre-load – essential for the adjusted bearings – is determined. In order to ensure this, both during the installation process and in operation, Schaeffler offers the Premesy pre-load measuring system.

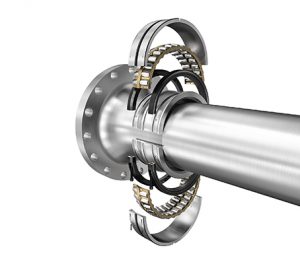

Furthermore, Schaeffler has developed a robust and innovative solution based on split asymmetric spherical roller bearings to ensure economical operation after a change of bearings. Worldwide, a large proportion of the drive train concepts installed on rotors are fitted with spherical roller bearings. If these bearings fail prematurely, the high replacement cost, e.g., for cranes, usually renders it uneconomical to replace them. The company’s solution using split asymmetric spherical roller bearings can reduce the cost of replacing the bearings by a good 50%. Since the entire replacement process takes place in the nacelle, it is not necessary to disassemble the rotor star or powertrain. All the necessary components are lifted into the nacelle using the deck crane and assembled in situ. Therefore, Schaeffler enables operators to continue to operate existing wind turbines cost-effectively.

Furthermore, Schaeffler has developed a robust and innovative solution based on split asymmetric spherical roller bearings to ensure economical operation after a change of bearings. Worldwide, a large proportion of the drive train concepts installed on rotors are fitted with spherical roller bearings. If these bearings fail prematurely, the high replacement cost, e.g., for cranes, usually renders it uneconomical to replace them. The company’s solution using split asymmetric spherical roller bearings can reduce the cost of replacing the bearings by a good 50%. Since the entire replacement process takes place in the nacelle, it is not necessary to disassemble the rotor star or powertrain. All the necessary components are lifted into the nacelle using the deck crane and assembled in situ. Therefore, Schaeffler enables operators to continue to operate existing wind turbines cost-effectively.

Major progress are also possible in the manufacture of rolling bearings in terms of CO2 footprint. Wind energy is second only to hydroelectric power as one of the most climate-friendly energy production technologies. However, emissions in the upstream chain are also considered, such as in the production and processing of steel to manufacture the various components of a wind turbine. In order to significantly reduce the carbon footprint of roller bearings, Schaeffler implements CO2 savings potentials across the entire value chain, from the procurement of the steel, through the manufacturing process, to the logistics and packing.

Finally, speaking about renewables, since 2021, Schaeffler has added its own hydrogen unit to its service offer. Together with the wind power sector, this works on new, integrated solutions that support the achievement of Schaeffler’s sustainability targets. Among other developments, an electrolyzer for the production of green hydrogen is scheduled to start operation at the Schweinfurt plant.

Stacks, the key components of these electrolyzers, form part of the Schaeffler product portfolio. The Schaeffler K-Series Hydron PowerStack will have an application range of 1 to 1.000 kilowatts. It will be designed and produced at Schaeffler sites in Europe, according to the highest quality standards. Electrolyzers can also be installed locally as modular systems. This makes it possible, for example, to link them with individual wind turbines.

Contenuti correlati

-

Wind turbine bearings test facility with Schaeffler and LORC

Schaeffler is cooperating with LORC (Lindø Offshore Renewables Center) and R&D Test Systems to build the world’s most powerful test facility for wind turbine main bearings in Lindø, Denmark. Schaeffler believes that the expansion of renewable energies is...

-

NSK expanding R&D centre and headquarters in China

NSK announced a major investment for the expansion of its R&D centre and headquarters in China. Located in Kunshan City, near Shanghai, a recent ground-breaking ceremony marked the start of construction. The development will further strengthen NSK’s...

-

Global PCR standards with SKF for bearings sustainability

Product Category Rules (PCR) for the bearing industry, initiated and driven by SKF, have been approved by The International EPD System. This will enable bearing purchasers to make more informed and sustainable choices, while also promoting greater...

-

Bearings simulation streamlined with new app SKF for Ansys users

The new SKF Bearing App for Ansys Mechanical simulation software offers design engineers an instant access to accurate stiffness data on more than 10.000 bearing designations. The app is available in the Ansys Store free of charge....

-

Linear motion solutions, Nadella Group acquired by The Timken Group

Nadella Group, a leading manufacturer of linear guides and systems and other specialized industrial motion solutions, is pleased to announce that The Timken Company, a global industrial leader in engineered bearings and industrial motion products, has reached...

-

High quality ceramic solutions in bearings, Schaeffler acquires Ceraspin

The automotive and industrial supplier Schaeffler has signed a contract with the Ceratizit Group for the acquisition of Ceraspin, thus strengthening its industrial business. Based in Livange, Luxembourg, Ceraspin has over 25 years’ experience in the development...

-

Magnetic bearings SKF increase sustainability in air compressors

SKF’s magnetic bearings, which can rotate at up to 50.000 rpm, are now playing a key role in reducing CO2 emissions across a range of industrial applications, including compressors. The technology has been indeed selected by Finnish...

-

Generalized bearing life model SKF obtains DNV certification

The SKF Generalized Bearing Life Model (GBLM) concept and the process leading to extensions of its applicability to special bearing design features and materials has been successfully audited by the independent certification body DNV. Calculating life expectancy...

-

Self-lubricant rolling bearings NSK for cryogenic gases applications

NSK has developed special rolling bearings that do not require external lubrication for use in submersible pumps that handle cryogenic gases, such as hydrogen and LNG. These stainless-steel bearings with a cage made of self-lubricating fluoroplastic are...

-

Green electricity in all five NSK European production plants

NSK has signed a contract with the electricity provider of its two UK manufacturing facilities in Newark (industrial bearings and linear guides) and Peterlee (automotive bearings) that ensures the supply of ‘green electricity’ generated from wind power....