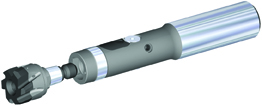

Reaming single carbide disc Widia

Widia developed the single carbide disc reamers in the Top Ream platform, for excellent reaming and hole finishing covering hole diameters up to 42 mm, with three TRF shank-styles starting at 14 mm and the TRM modular tool from 20 mm and up. Alternative to boring tools and conventional brazed carbide-tipped reamers, the Widia reaming solution Top Ream uses a single carbide disc and brazed joint, instead of four to eight (or more) individually brazed carbide tips, providing a strong connection that is virtually immune to thermal effects during machining operations.

In addition, carbide always provide a good center to locate on, ensuring a minimum of four ‘like new’ accurate regrinds, and also the single piece of carbide is inherently more stable and resistant to vibration. The through-hole style has an 18-degree left hand spiral, doing a great job of pushing the chip forward. The Top Ream TRM series’ mounting mechanism makes simultaneous contact on the cutting head’s face and taper, so that the reamer head pops out by simply twisting the locking screws, with no need for head to body orientation, providing a strong, vibration-free and precise reamer interface, with virtually zero run out. The reaming tools size range covers the lion’s share of application requests from customers, and offers a wide variety of custom geometries, diameters and edge preps, all available in three weeks or less.

Contenuti correlati

-

Quick and accurate digital boring head setup with Seco Tools

Seco Tools presents Seco Axiabore and Axiabore Plus digital axial boring heads, developed to eliminate tedious, inaccurate boring head adjustments that can lead to scrapped parts. Its wide digital display helps for quick, efficient adjustment and setup....

-

Further production capacity investments for BIG Kaiser in 2020

BIG Kaiser announced a range of investments in production, logistics and infrastructure, as well as the recruitment of additional customer-facing staff across Europe. The company is currently investing several million euros into new machines and machining centers,...

-

High-precision automated fine boring from Big Kaiser

The future of fine boring is being developed in Big Kaiser with the EWA system, an automatic fine boring tool that provides fully-automated machine tool operation without the need for a human operator. EWA makes fine boring...

-

Milling boring machine Soraluce awarded

Soraluce FXR Milling boring machine has been awarded with the Red Dot Award: Product Design 2016 among a record number of 5.214 participants. The machine represents the concept of the new range of Soraluce machines, based upon...