Precision hydraulic chuck BIG Kaiser for Swiss type turning machines

BIG Kaiser launched the new hydraulic chuck lathe Type B, specifically designed for Swiss type turning machines. This addition broadens the company’s extensive range of hydraulic chucks, underscoring its dedication to precision and innovation.

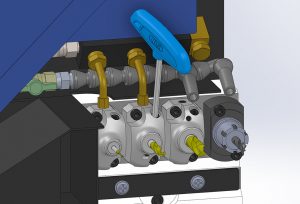

Type B is optimized for select Star Micronics machines. With an unmatched repeatability of less than 1 μm, this new addition features a rectangular design and multiple tool rows to accommodate the compact size of these machines. The design minimizes interference and enhances machining capabilities in space-constrained setups.

The hydraulic chuck lathe Type B expands BIG Kaiser’s lineup, adding to the Standard, F, and R Types with its tailored adaptability for unique machine requirements. The Standard model offers front tool clamping, the F Type allows rear operation in tight spaces, and the R Type, with its square shape, suits setups needing multiple tool rows without interference.

Hydraulic chucks are renowned for their precise lathe operations, offering very high repeatability and damping capabilities. Compatible with leading automatic Swiss type turning machine brands, including Citizen, Star, Tsugami, and Tornos, these chucks facilitate safe and swift cutting tool changes with a simple Allen-key, significantly enhancing operational efficiency and safety.

Hydraulic chucks are renowned for their precise lathe operations, offering very high repeatability and damping capabilities. Compatible with leading automatic Swiss type turning machine brands, including Citizen, Star, Tsugami, and Tornos, these chucks facilitate safe and swift cutting tool changes with a simple Allen-key, significantly enhancing operational efficiency and safety.

The versatility of the B Type (SL22B) and R Type (SL22R) chucks allows for their use in a broad array of Star machines, providing customers with the flexibility to choose the optimal chuck for their specific applications. The B Type is particularly suited for machines with a single-level tool post, while the R Type caters to dual-level posts, offering a tailored solution for every machine configuration.

Giampaolo Roccatello, chief sales & marketing officer for Europe at BIG Kaiser, reflects on the company’s 30-year history of hydraulic chuck production: “Since unveiling our first hydraulic chuck in 1994, we’ve consistently contributed to advancements in precision hydraulic chuck technology. Each chuck undergoes two thorough manual inspections before leaving our factory, ensuring it meets the highest quality standards”.