Lathe roughing strategy Esprit optimized

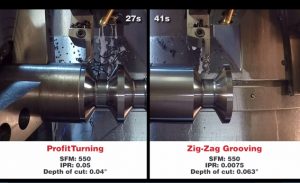

Esprit latest release of the Esprit CAM software includes ProfitTurning, a lathe roughing strategy that reduces machine cycle time from 41 to 27 sec, with higher precision, improved quality control and productivity. ProfitTurning is a high-speed lathe roughing strategy developed by DP Technology for OD/ID/face cutting and other tasks, fast secure and efficient, also extending tool life by minimizing wear.

The new toolpath technology employed uses the principles of physics to formulate unique strategies for cutting challenge, maintaining consistent cutting forces and chip loads, increasing cutting speeds. By employing trochoidal turning and controlled engagement techniques, ProfitTurning toolpath also reduces vibration and residual stresses, making it particularly suited to thin walls or hard materials, especially super alloys. In order to formulate unique optimized cutting strategies, the physics-based algorithm inputs all relevant factors, such as tool material, tool shape, workpiece material, tool speed, feed rate, chip deforming and load, machine tool power, acceleration and deceleration.