Float in 3D printing, F.lli Giacomello introduces additive manufacturing

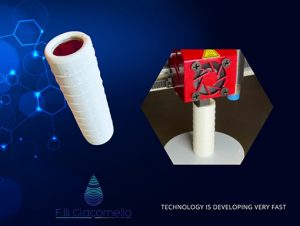

F.lli Giacomello is pleased to announce the launch of its first LMU float, an innovation made of nylon through the advanced 3D printing technology in use at the company.

This is an innovation which represents a notable advancement for the control of liquids sector: the ability to manufacture the product in a single block eliminates the need to create two separate shells as well as complicated welding processes, guaranteeing superior quality and unprecedented efficiency. Furthermore, the elimination of the use of glues to block the magnet not only improves the safety of the final product, but also speeds up production times, optimizing the entire production chain.

The flexibility of 3D printing also allows F.lli Giacomello to quickly and efficiently adapt production to market needs, whether for the creation of individual pieces or to produce solutions on a larger scale.

The company is therefore very proud to be at the forefront in the adoption of innovative technologies such as additive manufacturing, and is set to continue to surprise the market and final users with further progresses and future projects.

Contenuti correlati

-

Additive materials Stratasys qualifying for Aerospace applications

Stratasys announced that it is providing the public with baseline material qualification data for Antero 840CN03 filament material in collaboration with Lockheed Martin and the Metropolitan State University of Denver. The release of this qualification data allows...

-

Additive manufacturing Stratasys for the US Navy

The U.S. Navy is set expected to take delivery of eight Stratasys 3D printers by the end of this year as part of a 20 million USD contract that will see up to 25 Stratasys F900 systems...

-

Face shields 3D printed within the Stratasys coalition

The final goal is to produce 350.000 face shields leveraging 3D printing flexibility to meet the high demand coming from hospitals in the front line against the covid-19 pandemic. Stratasys has thus made up a coalition of...

-

Integrated additive and subtractive manufacturing with 3D Systems and GF Machining

Georg Fischer, GF Machining Solutions and 3D Systems partnered to enhance metal parts production, redefining how manufacturers think about their manufacturing environments. The partnership combines 3D Systems’ expertise in additive manufacturing with GF Machining Solutions’ precision machining,...

-

3D printed metal parts, agreement Siemens Trumpf

Siemens and Trumpf announced a partnership aimed to develop an end-to-end software solution to optimize and streamline additive manufacturing of 3D printed metal parts. The aim is to integrate and streamline the entire powder-bed-based laser metal fusion...

-

3D printing, PTC joins 3MF Consortium

PTC joined the 3MF Consortium as founding member, an industry association aimed to develop and promote a new full-fidelity file format for 3D printing. PTC is committed to bringing visibility of manufacturing capabilities to the design engineer...

-

3D printing Roboze distributed in Emea

Italian 3D printing manufacturer Roboze expanded its Emea distribution channel in France, appointing Kreos as official partner for the Country. After the launch of Roboze One+400 3D printer last april, an advanced solution for printing peek, PEI,...