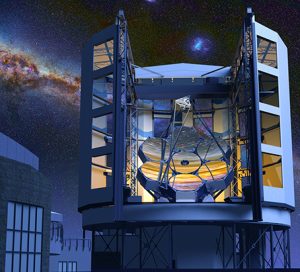

Camozzi and Ingersoll technology for the Giant Magellan Telescope

The Italian Camozzi Group, through its fully owned subsidiary Ingersoll Machine Tools headquartered in Rockford (Illinois), has entered into an agreement with GMTO, the organisation managing the development of the Giant Magellan Telescope (GMT) on behalf of its US and international founders, to build the telescope’s steel precision structure.

With its unique design, the GMT will produce images that are 10 times sharper than those from the Hubble Space Telescope in the infrared region of the spectrum. Ingersoll Machine Tools together with MT Mechatronics, located in Mainz (Germany), will design and manufacture the 1.300 tons precision mechanism, known as the ‘telescope structure’, that holds the GMT’s optics which will smoothly track the movements of celestial targets.

The telescope will be designed by MT Mechatronics and manufactured, assembled, and tested by Ingersoll before being shipped to, and installed at, the GMT observatory site high in the remote Chilean Andes. The structure of the telescope, complete with mirrors and all instrumentation, will weigh 2.100 tons and will float on a 50 microns thick oil film which will ensure frictionless movement to offset the earth’s rotation and follow the celestial bodies in their paths across the sky. This ‘hydrostatic’ technology was patented several years ago by INNSE, a Camozzi Group company, renowned throughout the world for this technology.

The total value of the telescope structure contract is $135 million and will require nine years of effort by a large workforce of engineers, designers, metal workers and machinists, and the structure is expected to be delivered to Chile at the end of 2025 and be ready to accept mirrors in 2028. The GMT will study the atmospheres of planets orbiting stars far from our solar system, in search of signs of biochemistry.