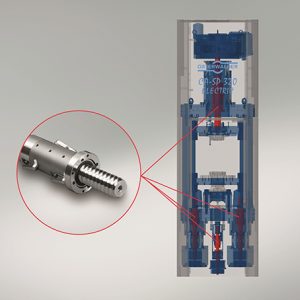

Ball screws NSK in powder presses from Osterwalder

The Switzerland-based Osterwalder AG is replacing hydraulic drives with servo-electric drives featuring NSK HTF series ball screws in its latest range of powder presses. The adoption of a Direct drive technology (DDT) with servo-electric motors and NSK HTF (High trust force) ball screws provides extra precision into the powder processing process, also achieving a reduction in energy consumption of around 80%.

The produced pressed parts also have fair higher dimensional accuracy, reducing the amount of finishing work, such as grinding with diamond wheels, and DDT cuts process and material costs. The DDT technology allows to position the systems to within 1 μm and achieves very high repeatability levels. The adoption of the ball screw drive solution also reduced the space required by the presses, and servicing is also simplified because there are no hydraulic control valves or other high-maintenance components, while working temperatures are more constant as no heat is being produced by the hydraulic system. Another benefit is the noise reduction, as servo-electric systems offer very quite operations.

Various NSK ball screws are used in the CA SP Electric and CA HM Electric series of drive systems adopted, moving the upper and lower die together simultaneously. It offers precise synchronization of linear movements in the presses, and HTF ball screws also permit very high traverse rates, thus helping minimize cycle times. As well as for carbide pressed parts, such as carbide inserts that are tipically produced using powder presses, the technology can also be applied to components made from iron powder, ceramic and magnetic materials. NSK’s HTF series have also been adopted widely by manufacturers of plastic injection moulding machines.

Contenuti correlati

-

First bioplastic retaining piece for ball screws by NSK

NSK S1 is the first bioplastic retention piece for ball screws to appear on the global market. Made from 100% renewable biological resources (mainly plants), the use of bioplastic for the new retaining piece reduces carbon footprint...

-

Deep-hole drilling IMSA with NSK DIN-standard ball screws

The new MF1000-3T deep-hole drilling machine from IMSA takes advantage of the benefits provided by NSK’s DIN-standard ball screws for the European machine tool market. The long-standing partnership between IMSA and NSK dates back many years and...

-

Eichenberger Gewinde ball screws for aggressive environment in space

Three robust, corrosion-resistant ball screws with end cap ball return by Eichenberger Gewinde, Carry Type KGE 16 x 16, ensure safe docking procedures of the space glider Dream Chaser, in its rendez-vous with the ISS in orbit....

-

NSK ball screws in automatic translation of moulds for injection moulding

Italy based Automationware has taken delivery of two special large ball screws from NSK aimed to facilitate the automatic translation of large moulds used in injection moulding machines. Located near Venice, Automationware was established in 2002 with...