Inductive rotary encoders Heidenhain for robot axes

The inductive rotary encoders KCI 1300 (singleturn) and KBI 1300 (multiturn) from Heidenhain are especially intended for compact motors in robotics and other applications.

Flat, lightweight and immune to both contamination and magnetic fields, these encoders feature a 25 mm hollow shaft and employ a scanning unit combined with either a screw-fastened circular scale or a press-fit disk/hub assembly. Wide mounting tolerances make installation easy. Mechanical fault exclusion ensures dependable mounting, and the EnDat 2.2 interface provides functionally safe data transmission. Because these encoders support an external temperature sensor, overload protection can be implemented for even greater reliability.

For two variants, Heidenhain wedded the electronics directly to a metal carrier that can act as a bearing cover for the motor. This fan-out technology (FOT) saves space, reduces the number of components and dissipates heat externally through the metal plate. The resulting KCI 1318 FOT and KBI 1335 FOT encoders come with a press-fit disk/hub assembly.

For larger 30 mm and 40 mm hollow shafts, Heidenhain offers the compact KCI 120 and KBI 136 inductive rotary encoders. Designed specifically for robotics applications, these encoders deliver the benefits of the smaller KBI 1300 series to robot axes that are significantly more heavy-duty.

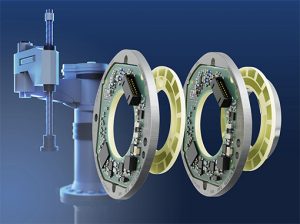

The encoder offering of the company for advanced robotics applications also features the Heidenhain KCI 120 Dplus dual encoder, a single device that provides position feedback from both the motor shaft and gearbox output shaft of a robot joint. Using robust inductive scanning technology, the encoder’s scanning head reads two separate circular scales for dual feedback. By measuring the gearbox output shaft, the KCI 120 Dplus can counteract design-induced inaccuracy on highly articulated and dynamic robots.

offering of the company for advanced robotics applications also features the Heidenhain KCI 120 Dplus dual encoder, a single device that provides position feedback from both the motor shaft and gearbox output shaft of a robot joint. Using robust inductive scanning technology, the encoder’s scanning head reads two separate circular scales for dual feedback. By measuring the gearbox output shaft, the KCI 120 Dplus can counteract design-induced inaccuracy on highly articulated and dynamic robots.

To ensure compatibility with as many applications as possible, the dual encoder comes in three variants featuring different hollow-shaft sizes and mounting dimensions for the scanning unit and two disk/hub assemblies. All three versions of the KCI 120 Dplus are compact, easy to integrate and equal in functionality.

The innovative KCI 120 Dplus widens the horizon of robot applications, making even high-accuracy machining tasks possible. And thanks to its EnDat 2.2 serial data interface, which is designed for functional safety, this dual encoder also thrives in safety-critical applications such as cobots.

Contenuti correlati

-

New advanced robotics hub for Universal Robots and MiR in Denmark

Universal Robots, the Danish collaborative robot (cobot) company, and Mobile Industrial Robots (MiR), the Danish manufacturer of AMRs (autonomous mobile robots), celebrated on May 14 the grand opening of their new 20,000 sqm headquarters in Odense, Denmark....

-

Force torque sensor by Bota Systems for high sensitivity in cobots

Bota Systems has unveiled the new force torque sensor SensONE T5, a highly sensitive iteration of its existing SensONE sensor, developed for small payload cobots. The SensONE T5 boasts an exceptional sensitivity level of 0.05 N /...

-

Strong end of 2023 and new heavy payload cobots for Universal Robots

Universal Robots, the Danish collaborative robots (cobots) company, has reported Q4 revenue of USD 103 million, up 21% on Q4 2022, representing the company’s largest revenue quarter to date. Overall 2023 annual revenue was USD 304 million,...

-

Cobot integration, partnership between Universal Robots and Denali

Universal Robots, the Danish producer of collaborative robots (cobots), has announced a new partnership with Denali Advanced Integration, a leading services and global technology integrator. Denali has become Universal Robots’ largest Certified Solution Partner (CSP). It is...

-

Motion control and factory automation, Bosch Rexroth acquires Elmo Motion Control

Bosch Rexroth invests in the expansion of its factory automation business and agreed to acquire the motion control specialist Elmo Motion Control Ltd, headquartered in Petach-Tikva, Israel. Elmo develops and produces electrical high-end servo drives and motion...

-

Direct drive motors for robots, Genesis Robotics opens new office in Germany

Genesis Robotics & Motion Technologies, manufacturer of LiveDrive, a high torque density direct drive motor for robotics and automation, announced that it will open an office in Frankfurt, Germany, to better serve the highly innovative and rapidly...

-

Cobots Omron assist expert welders in Guidetti Technology

Guidetti Technology SRL has integrated Omron collaborative robots (cobots) into its ‘EasyArc’ welding solution. This is used in collaborative applications on small batches of various types of metal carpentry. Based in Modena, Italy, Guidetti has 50 years...

-

Schaeffler strengthens robotics business with acquisition of Melior Motion

Schaeffler has signed an agreement to acquire all of the shares of Melior Motion GmbH, a supplier of precision gearboxes for robotics and other applications in automation. The operation expands the robotics portfolio of the Schaeffler Group’s...

-

Record annual revenue for Universal Robots in 2021

Universal Robots, the Danish producer of collaborative robots, has reported record annual revenue of USD 311 millions, 41% up on 2020 and 23% up on pre-pandemic results in 2019. The company’s president, Kim Povlsen said: “Universal Robots...

-

Digital automation lab opening in Reggio Emilia with Comau

Comau and Fondazione REI (Reggio Emilia Innovation, part of the Italian industrial association Unindustria Reggio Emilia) have partnered to create DAL – Digital Automation Lab. Combining Comau’s long experience in the field of industrial innovation with REI...