More metal materials EOS for series additive manufacturing

-

- Tweet

- Pin It

- Condividi per email

-

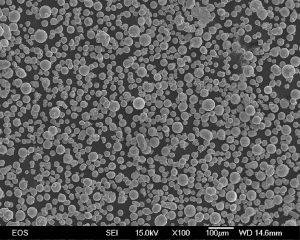

EOS developed four new additive manufacturing metal materials tailored to suit a broaden array of applications, ranging from automotive to the medical sector. The company also offers comprehensive data on the material properties of all four metals, such as the number of test specimens on which the mechanical properties are based on, as well as detailed scanning electron microscope (SEM) images that provide an insight into the material quality.

Thus, EOS is providing companies with documentation and transparency for production, making it easier for to compare DMLS 3D printing with traditional manufacturing technologies and other 3D printing technologies. Such data and openness are a requirement for the use of additive manufacturing (AM) in series production. The four new materials are EOS StainlessSteel CX, EOS Aluminium AlF357, EOS Titanium Ti64 Grade 5, and EOS Titanium Ti64 Grade 23.

In detail, EOS StainlessSteel CX is a new tooling grade steel developed for production with the EOS M 290 that combines excellent corrosion resistance with high strength and hardness. Components made from this material are easy to machine and enable an excellent polished finish.

EOS Aluminum AlF357 is the ideal material for applications that require a light metal with excellent mechanical/thermal strength. Components made from this material are characterized by their light weight, corrosion resistance and high dynamic loading. The materials has been specially developed for production with the EOS M 400, but it is planned to also make the material available for the EOS M 290 system in the near future.

EOS Titanium Ti64 Grade 5 has been specially developed for its high fatigue strength without hot isostatic pressing (HIP). Suitable for production with the EOS M 290, the material also offers excellent corrosion resistance, making it ideal for aerospace and automotive applications.

EOS Titanium Ti64 Grade 23 has also been specially developed for its high fatigue strength without hot isostatic pressing (HIP) and for production with the EOS M 290. Compared to Ti64, Ti64 Grade 23 offers improved elongation and fracture toughness with slightly lower strength. Thanks to these properties, it is particularly well suited to medical applications.

Contenuti correlati

-

Additive metal powder capacity increased for Sandvik

Sandvik continues to invest in metal powder capacity for additive manufacturing (AM) by installing two additional atomization towers at the production site in Neath, U.K. This expansion follows a recent investment in a new plant for the...

-

Metal adhesives activators solvent free by Delo

Delo presents two new solvent-free activators accelerating the adhesion build-up of metal adhesives, the low-viscous Delo-Quick 5910 and the hight-viscous Del-Quick 5975. Activators are employed to reduce the curing time of metal adhesives, but usually most products...

-

Liquid level visual indicator plugs F.lli Giacomello

The LMA tank plugs from F.lli Giacomello are liquid level visual indicator plugs realized with a body in aluminum alloy D11S. The devices have an oil proof gasket, also available in aluminum or fibre on request. For...

-

Revenues growth in 2016 for Scm Group

Successful year 2016 for Scm Group, with revenues increased to 600 million euros, compared to the 513 million of 2015. The italian Group is specialized in the production of industrial machinery and components, with a strong position...

-

Soluble coolants highly stable Castrol

Castrol soluble coolants Hysol SL 35 XBB and Alusol SL 51 XBB reinvent the fundamentals of cutting fluid technology by maintaining constants pH levels (9-9,5), meaning stable conditions exceeding lifetime expectations of other standard cutting fluids. The...

-

Water-jet cutting system by CMS Industries

CMS Industries presents Idroline S, a water-jet cutting robot developed to provide higher technological and productive performances. The system has been engineered with specific structural solutions for the water-jet cutting technology, for applications with several materials such...

-

Linear motion Rollon at Innotrans 2016

The italian company Rollon is bringing to Innotrans 2016 its developments in the linear motion products and solutions for the railway sector, enriched after the acquisition of the german company Hegra, specialized in the production of highly...

Scopri le novità scelte per te x

-

Additive metal powder capacity increased for Sandvik

Sandvik continues to invest in metal powder capacity for additive manufacturing (AM) by installing two additional atomization...

-

Metal adhesives activators solvent free by Delo

Delo presents two new solvent-free activators accelerating the adhesion build-up of metal adhesives, the low-viscous Delo-Quick 5910...

Economy read all ▶

-

Simulation in motorsport for Peugeot Sport hypercar with Dassault Systèmes

Dassault Systèmes and Peugeot Sport, the motorsports division of Stellantis, announced their partnership to...

-

RF rotary joints, Servotecnica signs agreement with Diamond Antenna

Servotecnica announces the agreement signed with the US company Diamond Antenna, supplier of world-class...

-

New advanced robotics hub for Universal Robots and MiR in Denmark

Universal Robots, the Danish collaborative robot (cobot) company, and Mobile Industrial Robots (MiR), the...

Technology read all ▶

-

Two-stage pressure regulator Emerson for hydrogen-powered vehicles

Emerson has introduced a new two-stage pressure-reducing regulator intended to maximise efficiency and improve...

-

High payload vertical articulated robot Mitsubishi Electric

Mitsubishi Electric has launched the Melfa RV-12CRL vertical articulated robot, which offers 1,504 mm...

-

Highly reliable pressure sensor Parker Hannifin for hydraulic applications

Parker Hannifin has introduced the SCP09 pressure sensor, a versatile and reliable solution for...