Polymer Victrex for drilling electrical connector

Oil & gas electrical connector specialist Rampart Products has specified Victrex HT polymer for a new HPHT (high-pressure high-temperatures) KTK (Kintec) electrical connector for the efficient and safe transmission of power and data during drilling processes. The multi-pin connector is a crucial component in oilfield equipment, and Rampart Products reports that the Victrex HT-based connector has more than twice the impact resistance of the traditional glass-reinforced epoxy constructed connectors, providing greater reliability in use by reducing cracking and chipping.

The high-performing polymer also avoids dust generation, usual happening with epoxy connectors, caused by vibrations within the tool, which may cause electrical shortages and costly downtimes. The material as well as the connector has been tested beyond industry standards, such as Norsok and ISO, in real-world environment simulations. The new connector had to be rated for temperatures beyond 200° C and pressures at 1.380 bar. The introduction of the first company’s connector using Victrex Park polymer also allowed a more efficient manufacturing, facilitated through rapid injection molding. The education and processing support provided by Victrex in both the development phase and the molding process have convinced Rampart to also look at other Victrex high performing polymers for future applications.

Contenuti correlati

-

Solid carbide drill Kennametal for ISO-P steels

Kennametal has introduced an expansion of its solid carbide drilling portfolio, the HPX drill for high performance, large volume drilling in steel. Designed to quickly and efficiently punch holes up to 8 x D in any ISO-P...

-

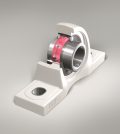

Re-lubrication-free bearings NSK in milk production

NSK proposed re-lubrication free bearings to a UK-based milk processing plant, in order to eliminate regular bearing failures on one of its principal conveyors. Proposed after a comprehensive evaluation of the company’s value added program AIP, the...